What Are the Commonly Used SMT Fixtures?

In the PCB assembly process, a variety of auxiliary tools are indispensable, such as stencils and different types of fixtures. Among them, fixtures play a critical role in improving production efficiency and ensuring product quality. In actual manufacturing, the most commonly used fixtures can be generally classified into three categories: reflow fixtures, depaneling fixtures, and test fixtures. The following section provides a detailed introduction to the functions and application scenarios of these three types of fixtures.

1. Reflow Fixtures

In SMT assembly, reflow soldering and wave soldering are key processes that directly determine soldering quality. To ensure that PCBs remain stable under high-temperature conditions and to prevent board warpage or component displacement, SMT reflow fixtures are widely used. As an essential auxiliary tool in PCB assembly manufacturing, reflow fixtures play an important role in improving soldering yield and product reliability.

A reflow fixture is a dedicated fixture used to support, hold, and secure PCBs during the reflow or wave soldering process. Its primary function is to protect the circuit board in high-temperature environments, preventing defects such as board deformation, component drop-off, or soldering issues caused by uneven heating, gravity, or airflow impact.

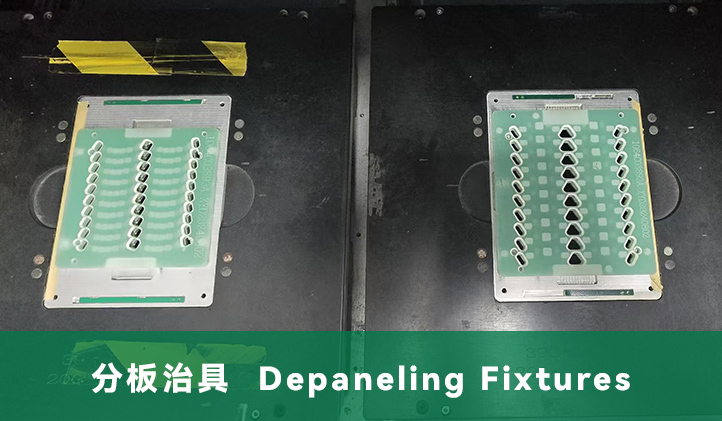

2. Depaneling Fixtures

During PCB assembly, boards are usually manufactured in panel form. After component assembly and soldering are completed, the boards must be separated into individual PCBs for final assembly or testing. At this stage, depaneling fixtures are required.

A depaneling fixture is a specialized tool used to fix, support, and position PCB panels during the depaneling process. It is commonly used in conjunction with V-cut depaneling machines, blade-type depaneling machines, or routing depaneling machines. By ensuring stable positioning and even stress distribution during depaneling, these fixtures help reduce mechanical stress on solder joints and electronic components.

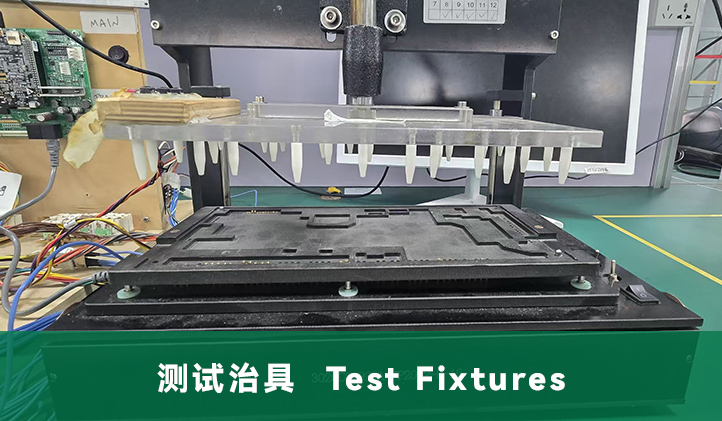

3. Test Fixtures

As the name suggests, test fixtures are used to assist in PCB testing. After PCB assembly is completed, whether the circuit board truly meets design specifications and functional requirements must be verified through systematic testing. Test fixtures serve as a critical interface between the assembled PCB and the testing equipment.

Test fixtures are custom-designed according to the PCB structure and testing requirements. They are used to position and secure the PCB while providing reliable electrical connections during testing. With the use of test fixtures, continuity checks, parameter measurements, and functional verification can be performed quickly and efficiently, effectively avoiding errors and inefficiencies associated with manual wiring.