What does PCB impedance mean?

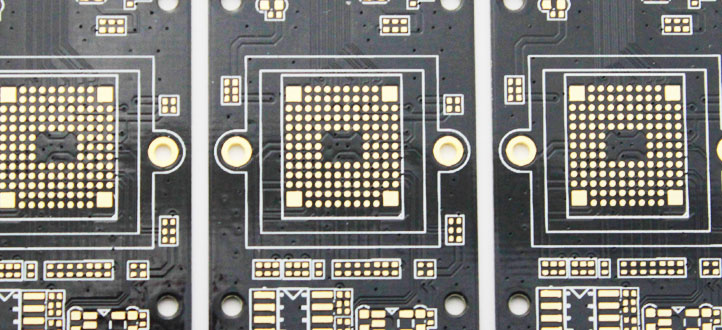

PCB manufacturing is a complex and crucial process that involves consideration of various parameters and characteristics. Among them, PCB impedance is a critical factor that directly affects circuit performance and signal transmission quality. This article will delve into the concept of PCB impedance, its significance, and its application in electronic manufacturing.

The Concept of PCB Impedance

PCB impedance refers to the resistive property encountered by current passing through PCB traces or signal transmission lines. Impedance is typically measured in ohms (Ω), representing the resistance to the flow of current. In electronic devices, PCB impedance plays a role similar to the flow of water in pipes – current transmission through traces and signal lines also encounters resistance.

The Importance of PCB Impedance

In PCB manufacturing, the significance of impedance cannot be underestimated. Different PCB designs may require varying impedance values, especially for high-frequency and high-speed circuits, where impedance control is crucial. Properly controlling PCB impedance offers the following advantages:

1. Signal Transmission Quality: Accurate impedance control ensures the quality of signal transmission, reducing signal distortion, crosstalk, and reflections, thereby maintaining signal stability and integrity.

2. Power Consumption Reduction: Well-designed impedance can lower power consumption during signal transmission, improving circuit energy efficiency.

3. Interference Resistance: Adequate control of PCB impedance enhances circuit immunity to interference, reducing the impact of external disturbances on signal transmission.

4. Stability: Impedance stability directly influences circuit stability and reliability, ensuring the proper functioning of electronic devices.

Controlling and Calculating PCB Impedance

In PCB design, precise calculation and control of impedance are complex tasks. Impedance is influenced by various factors, including PCB layer stack-up, trace width and spacing, substrate materials, and signal transmission frequency. Design engineers typically use specialized PCB design software for impedance calculation and simulation.

For high-frequency and high-speed circuits, impedance control is particularly critical. In such applications, even minor impedance variations can lead to signal distortion and performance degradation. Therefore, strict adherence to impedance requirements and conducting practical testing during the design and manufacturing process is essential.

Conclusion

PCB impedance is a crucial parameter in modern electronic manufacturing, directly affecting circuit performance stability and signal transmission quality. In PCB design and manufacturing, accurate impedance calculation and control are pivotal in ensuring proper circuit operation and stable performance. By employing well-designed impedance, electronic devices can achieve excellent signal transmission quality, stability, and reliability, providing outstanding electronic products and systems for various applications.