What detection equipment is used in the PCBA manufacturing process?

PCB assembly is an indispensable part of modern electronic manufacturing, involving circuit board assembly, welding, testing, and many other aspects. In order to ensure the quality and reliability of PCBA manufacturing, various detection equipment needs to be used for testing and verification during the manufacturing. This article will introduce the commonly used detection equipment in PCB assembly.

Firstly, X-ray detectors are one of the most commonly used detection equipment during PCB assembly. X-ray detectors can detect the quality of solder joints, such as the position, quality, and integrity of solder joints. In addition, X-ray detectors can also detect whether the components on the PCBA board are correctly installed and whether there are short circuits or open circuits. Through X-ray detectors, various problems on the PCBA board can be quickly and accurately detected, improving the quality and performance of the product.

Secondly, SPI is another commonly used detection equipment in PCBA manufacturing. SPI stands for Solder Paste Inspection, which is used to detect the quality and position of solder paste to ensure that the coverage area and height of the solder paste meet the standards. SPI can quickly identify and correct problems in the early stages of the manufacturing process, thereby reducing manufacturing defects and production costs. SPI can be combined with other detection equipment to achieve comprehensive PCBA board testing and verification.

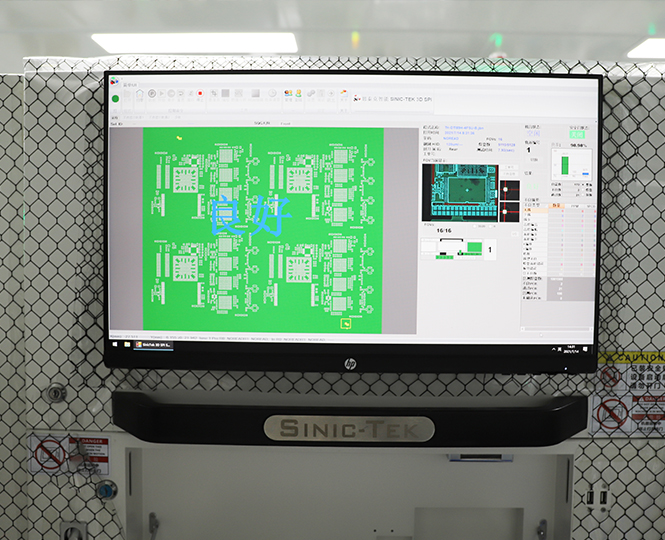

Another commonly used detection equipment is AOI, which stands for Automatic Optical Inspection. AOI can detect whether the components on the PCBA board are correctly installed and whether there are short circuits or open circuits. AOI can detect various defects on the PCBA board, such as displacement, deviation, and defects, and timely detect and correct problems during the manufacturing. AOI can greatly improve manufacturing efficiency and quality, reducing manual operation and errors.

In addition, optical microscopes are also commonly used in PCBA manufacturing. Optical microscopes can detect the position, quality, and integrity of the components on the PCBA board. At the same time, optical microscopes can also detect the surface quality of the PCBA board, such as oxidation and solder paste problems. In addition, there are many other detection equipment used in PCBA manufacturing, such as automatic testers and environmental test chambers. These equipment can conduct various tests on the PCBA board, such as electrical performance tests and environmental adaptability tests.

In conclusion, commonly used detection equipment for PCB assembly include electronic microscopes, X-ray detectors, SPI, and AOI, etc. By using these detection equipment, the quality and reliability of the PCBA board can be ensured, thereby improving the quality and performance of the product. At the same time, there are many other detection equipment that can be used in various aspects of PCB assembly, achieving comprehensive testing and verification.