What are the electronic assembly soldering processes?

1. Reflow Soldering

Reflow soldering is a welding process in SMT patch processing, which mainly uses solder paste. The process is carried out after solder paste printing and component mounting. Reflow means that the solder paste is initially solid metal particles, and then it melts into liquid state with the high temperature inside the furnace. After cooling, it solidifies again, which is why it is called reflow soldering. Reflow soldering is suitable for use when PCB size and component size are small. With the continuous advancement of technology, the size of PCBs is becoming smaller and smaller, so the application of reflow soldering is becoming more and more extensive.

2. Wave Soldering

Wave soldering is a welding process in DIP processing, which mainly uses solder bars. Different from reflow soldering, wave soldering needs to be used when PCB or component size is larger. Wave soldering is completed with the help of a wave soldering machine. During the soldering process, high temperature melts the solder bars into liquid tin, which will form a wave-like phenomenon under the operation of the device. This is also why it is called wave soldering.

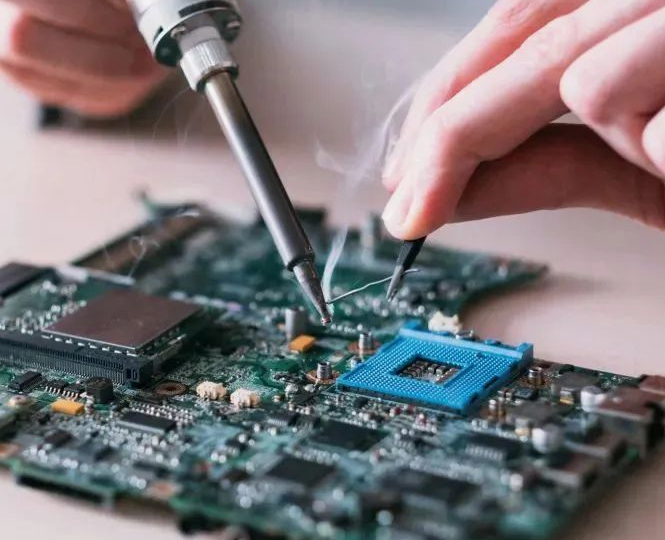

3. Post-soldering

Post-soldering is a manual soldering method, which mainly uses solder wires and requires tools such as soldering irons. Because it is a manual operation, its soldering speed is relatively slow. Post-soldering is mainly used to process products that cannot be processed by reflow soldering or wave soldering. There are many electronic components that cannot withstand the high temperature of reflow soldering or wave soldering, or electronic components that are too high to enter the wave soldering machine. In these situations, post-soldering processing is needed.