How many types of PCBs are there?

PCB, or Printed Circuit Board, is a crucial component in electronic products. It connects electronic components through printed wires to form functional circuits in electronic devices. During the PCB assembly process, different PCB types are suitable for different designs and application scenarios. So, how are PCBs classified? Let's explore several common classification methods for PCBs.

Firstly, PCBs can be classified based on the number of layers. They are categorized as single-layer PCBs, double-layer PCBs, and multi-layer PCBs. Single-layer PCBs consist of a single layer of copper foil covering the substrate, suitable for simple circuit designs and low-cost applications. Double-layer PCBs have two layers of copper foil on both sides of the substrate, connected through holes to establish circuit connections. They accommodate more complex circuit designs and offer higher wiring density. Multi-layer PCBs comprise three or more copper foil layers distributed among multiple substrate layers. They form intricate circuit structures through internal via connections. Multi-layer PCBs are commonly used in complex electronic devices and applications requiring high-density wiring, as they provide greater wiring space and improved electromagnetic shielding capabilities.

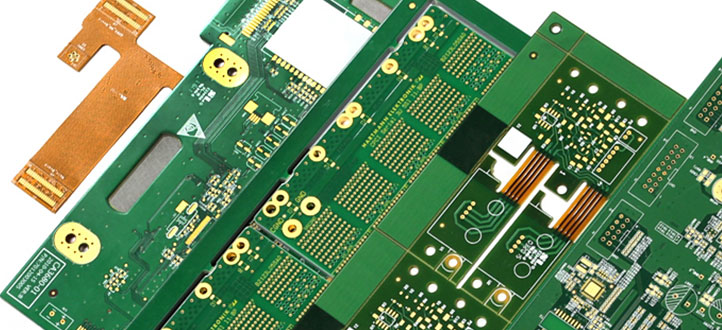

Secondly, PCBs can be classified based on the material type. The most common classifications are rigid PCBs and flexible PCBs. Rigid PCBs utilize rigid substrate materials such as FR-4, suitable for most conventional electronic devices. Flexible PCBs employ flexible substrate materials like Polyimide (PI), allowing bending and folding, making them suitable for applications requiring flexibility or compact layouts. Additionally, there is a combined type called rigid-flex PCB, which combines the advantages of both rigid and flexible PCBs, catering to specific design requirements.

Furthermore, PCBs can be classified based on the application field. General-purpose PCBs are suitable for a wide range of applications such as consumer electronics, communication devices, etc. They possess more generic design and manufacturing requirements. On the other hand, there are specialized PCBs designed and manufactured to meet specific industry or application requirements. Examples include medical equipment PCBs, aerospace PCBs, which often need to meet specific safety, reliability, and environmental requirements.

Moreover, PCBs can be classified based on their performance characteristics. High-frequency PCBs are designed for high-frequency signal transmission and RF applications. They require special designs and material selection to ensure low signal loss and good signal integrity. High-speed PCBs are designed for high-speed signal transmission and data communication. They demand more sophisticated wiring and lower transmission latency. High-temperature PCBs are designed to operate in high-temperature environments, requiring the use of temperature-resistant materials and special thermal management designs.

Lastly, PCBs can be classified based on special manufacturing processes. For instance, blind via PCBs refer to holes that only pass through one side of the PCB, rather than going through from the other side. Buried via PCBs involve holes formed internally within the PCB, connecting circuits by filling them with conductive materials. Multi-layer printed circuit boards are formed by interconnecting multiple layers of circuit boards.

In summary, PCBs can be classified based on layers, materials, application fields, performance characteristics, and manufacturing processes. Different classification methods are suitable for different design requirements and application scenarios. Choosing the right type of PCB is crucial for meeting design requirements, improving circuit performance, and reliability. With advancing technology and expanding application fields, the classification and design of PCBs will continue to evolve to meet ever-changing demands.