What is PCB flying probe test?

When it comes to PCB manufacturing, ensuring the quality and performance of circuit boards is crucial. In modern electronic devices, PCBs play a key role in connecting and supporting various electronic components. However, even in carefully designed and manufactured PCBs, there may still be some potential electrical issues. These issues can lead to poor connections, component failures, and even affect the functionality of the entire device. To ensure that each PCB operates as expected, PCB flying probe testing emerges as a critical testing method.

Overview of PCB Flying Probe Testing

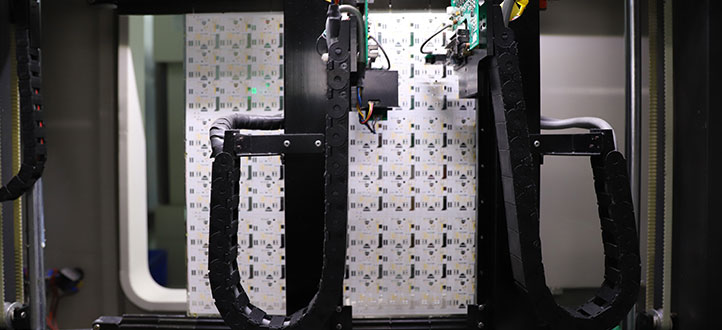

PCB flying probe testing, also known as "probe testing" or "automated testing," is an automated testing method used in the PCB manufacturing process to detect electrical connectivity and functionality. It aims to identify and eliminate potential issues that may arise during the manufacturing process, ensuring that each produced PCB meets high-quality standards.

Working Principles of Flying Probe Testing

In flying probe testing, a set of specially designed probes (often referred to as "flying probes" or "test probes") is used. These probes automatically make contact with various electronic components, connections, and traces on the PCB. The probes' contact can send electrical signals and monitor responses, thereby determining the presence of electrical issues. These issues may include poor soldering, shorts, opens, or other connectivity problems.

Advantages of PCB Flying Probe Testing

PCB flying probe testing offers multiple advantages, particularly when dealing with high-density multilayer PCBs. Here are a few advantages:

1. Automation and Efficiency: PCB flying probe testing is an automated testing method that can rapidly test complex circuit boards. This greatly enhances testing efficiency and reduces the time required for manual testing.

2. Comprehensiveness: Flying probe testing can cover the entire PCB's circuitry, detecting potential issues. This ensures that all electrical connections are validated.

3. Testing High-Density PCBs: For high-density multilayer PCBs, traditional manual testing methods can become challenging. Flying probe testing can simultaneously test multiple connections and traces in a short period.

4. Accuracy: Flying probe testing employs high-precision probes, enabling the accurate detection of electrical issues, including minor connectivity problems.

Applications of Flying Probe Testing

PCB flying probe testing finds widespread applications in the electronics manufacturing industry. It is used in various electronic products, ranging from consumer electronics to industrial equipment and communication devices. Whether for small-scale or large-scale electronic devices, ensuring the quality and performance of PCBs is paramount, and this is precisely what PCB flying probe testing can provide.

In the process of PCB manufacturing, PCB flying probe testing serves as a critical automated testing method, ensuring the electrical connectivity and functionality of circuit boards. By swiftly and comprehensively testing PCBs, flying probe testing enhances production efficiency and guarantees that each PCB functions correctly. In modern electronics manufacturing, PCB flying probe testing is not just a technology; it's a vital assurance of quality.