The role of PCB solder paste layer?

In today's digital age, the ubiquitous electronic products around us owe their existence to an important foundation called Printed Circuit Board (PCB). It serves as the connection platform for various electronic components, acting as the brain and nervous system of the electronic world. In the manufacturing process of PCBs, there is a magical layer called the "Solder Paste Layer," which plays a crucial role in the PCB assembly process.

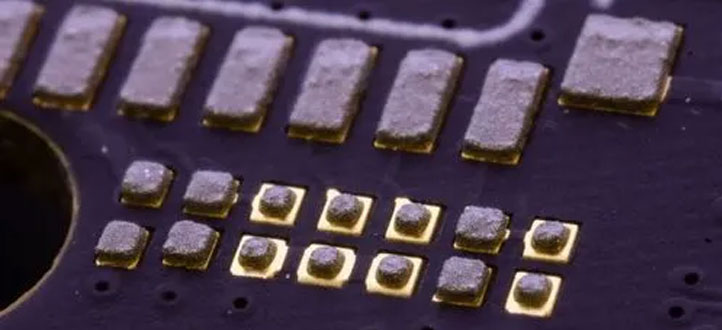

The PCB Solder Paste Layer refers to a special level on the PCB that defines the positions and shapes of solder pads, facilitating the surface mount technology (SMT) process of mounting electronic components onto the PCB. Solder pads are the contact points where electronic components are soldered onto the PCB. The precise positioning and size of these solder pads are vital, as they determine the correct placement and alignment of the components, ensuring that they are mounted accurately on the PCB.

The Solder Paste Layer is usually represented as an independent level, typically in white or other contrasting colors to facilitate recognition by PCB designers and manufacturers. On the Solder Paste Layer, the solder pads are depicted with appropriate dimensions to match the package size of the components.

During the SMT process, a layer of solder paste is applied to the solder pads. Once the electronic components are mounted on the solder pads, the solder paste melts and forms solder connections with the component pins and the pads during reflow soldering, achieving electrical connections and fixation.

The PCB Solder Paste Layer plays a crucial role in the SMT process by ensuring the correctness and consistency of the solder pads, thereby guaranteeing the reliability and excellent soldering quality of the components. Proper design of the Solder Paste Layer is essential to achieve high-quality PCB assembly. Therefore, during the PCB design process, designers need to carefully consider the positions and dimensions of the solder pads and select appropriate solder paste types and process parameters to ensure the successful implementation of the SMT process.