What is the process of smt processing?

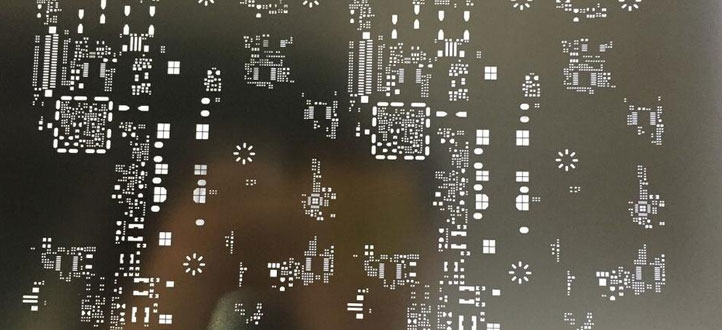

Firstly, an SMT steel stencil is a metal template typically made of stainless steel or nickel alloy. It features precise hole patterns that control the distribution and exact placement of solder paste during the printing process. The hole sizes and arrangement on the stencil match the layout of solder pads on the PCB, ensuring accurate deposition of solder paste onto the target pads. Through the use of the steel stencil, precise component placement and reliable soldering can be achieved.

Secondly, the primary function of an SMT steel stencil is to facilitate precise solder paste printing. In the SMT process, solder paste is used as an adhesive between components and the PCB to establish electrical connections and enable soldering. The holes on the steel stencil allow solder paste to be deposited in the appropriate quantity and precise locations on the PCB's solder pads. This ensures soldering quality and consistency while reducing the occurrence of soldering defects and quality issues.

The manufacturing process of SMT steel stencils is also critical. Common fabrication methods include chemical etching, laser cutting, and electroforming. Chemical etching involves a series of steps, including photolithography, lamination, exposure, development, and etching, to produce the stencil from a metal sheet. Laser cutting utilizes a laser head controlled by a computer to precisely cut the desired hole patterns on the metal sheet. Electroforming involves processes such as photolithography, lamination, exposure, and electroplating to create the stencil. Each fabrication method has its own advantages and disadvantages, and the appropriate method can be chosen based on specific requirements.

In the SMT process, the importance of SMT steel stencils cannot be overstated. They ensure precise solder paste printing, providing accurate component placement and precision for subsequent assembly steps. Accurate solder paste deposition and consistent soldering quality are crucial for the performance and reliability of electronic products.

In addition to providing precise printing functionality, SMT steel stencils offer several other advantages. Firstly, they have a long lifespan and durability, capable of withstanding multiple printing operations. Secondly, the stencils are easily replaceable and maintainable, accommodating different PCB designs and printing requirements. Moreover, they provide a certain level of protection, guarding against contamination and external environmental factors that may affect printing quality.

In summary, SMT steel stencils hold a significant position and play a crucial role in the SMT process. They ensure soldering quality and reliability through precise printing and accurate solder pad layouts. The manufacturing process of SMT steel stencils is crucial, and different fabrication methods can meet various needs. Correctly selecting and utilizing SMT steel stencils is vital for achieving high-quality PCBA assembly. As technology continues to advance, SMT steel stencils will further develop and optimize to meet evolving process requirements and the demands of electronic products.