What are the SMT process flows?

The SMT patch process generally includes the following steps:

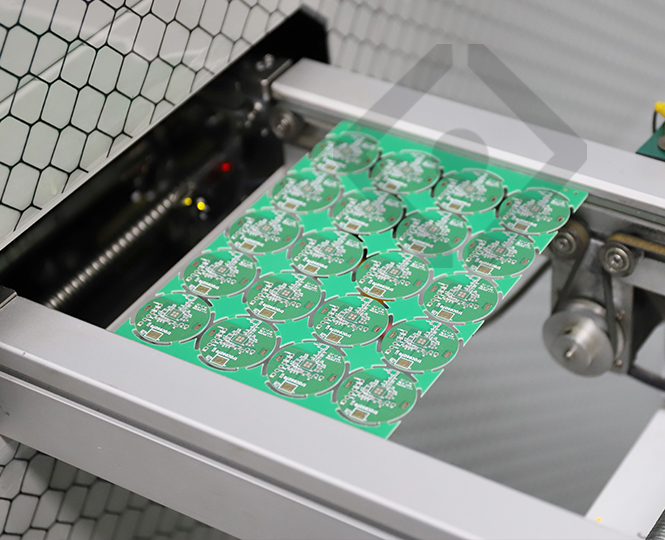

1. Preparation of PCB, components, and stencil: SMT patching technology is to mount electronic components on the PCB board. Therefore, before patching, a series of preparatory work needs to be done for PCB and electronic components, such as cleaning and baking, and the stencil needs to be designed according to the PCB data for subsequent printing work.

2. Printing of solder paste: Solder paste is a special adhesive mainly composed of tin, used to adhere the components to the PCB. In the SMT patching process, a special solder paste printer needs to be used to print the solder paste on the surface of the PCB through the stencil. The process of printing solder paste needs to be very precise and meticulous to ensure the welding quality, and SPI inspection is also required after printing.

3. Component mounting: After SPI inspection, an automatic component mounting machine is used to mount the components on the PCB. The automatic component mounting machine can automatically take out the components from the reel according to the pre-programmed program and mount them on the PCB. During the component mounting process, attention needs to be paid to the position and direction of the components to ensure that they are correctly installed on the PCB.

4. Welding: After the components are mounted, welding needs to be performed. In the SMT patching process, there are usually two welding methods: hot air welding and reflow welding. Hot air welding places the PCB in a hot air furnace for welding, while reflow welding places the PCB in a reflow furnace for welding. During the welding process, temperature and time need to be controlled to ensure the quality of the welding.

5. Inspection and repair: After completing the SMT patching process, inspection and repair are required. The purpose of inspection is to ensure the quality and reliability of the patching, and the purpose of repair is to fix any problems that may exist. There are multiple inspection and repair methods, including AOI, visual inspection, and X-ray inspection.

In summary, SMT patching technology is a very important technology in modern electronic manufacturing industry. Through sophisticated process flow and strict quality control, high-efficiency, high-quality, and high-reliability circuit board manufacturing can be achieved.