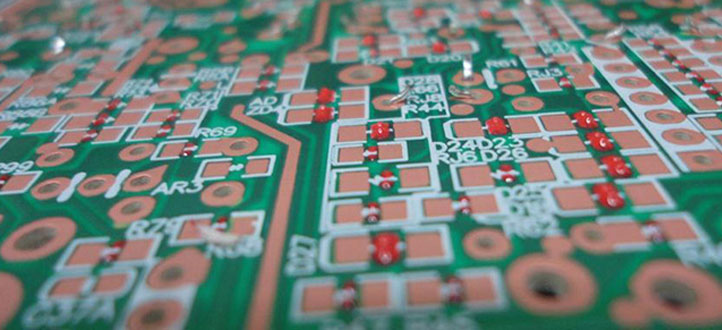

What is SMT red glue process?

SMT Red Glue Technology is a process used in PCB assembly and is a part of Surface Mount Technology (SMT), which has become the mainstream method for electronic component assembly in modern electronics manufacturing. SMT technology is widely adopted due to its efficiency, precision, and reliability. Within the SMT process, Red Glue Technology plays a crucial role by providing additional protection and support to electronic assemblies, thus improving the quality and reliability of electronic products. This article will delve into the principles, applications, and significant role of SMT Red Glue Technology in electronics manufacturing.

What is SMT Red Glue Technology?

SMT Red Glue Technology is an auxiliary process within the SMT technology that utilizes special adhesive material (red glue) to secure and protect electronic components on the Printed Circuit Board (PCB). The red glue is typically a two-component adhesive that needs to be mixed in specific proportions before use, ensuring its viscosity and flowability are suitable for red glue printing.

In the SMT Red Glue Technology, the pre-mixed red glue is placed on a red glue stencil. Subsequently, an automated printing machine or a squeegee is used to evenly spread the red glue onto specific locations on the PCB. The hole patterns and dimensions on the red glue stencil determine the layout of the adhesive. Next, electronic components are mounted onto the red glue. The red glue stabilizes the components' positions and provides support during the subsequent soldering and curing processes. Finally, the red glue undergoes a curing process, usually through heating or exposure to ultraviolet radiation. The cured red glue maintains the components' positions and provides protection.

Applications of SMT Red Glue Technology

SMT Red Glue Technology finds extensive applications in electronics manufacturing, especially in industries requiring high stability and vibration resistance for electronic components, such as automotive electronics, aerospace, and medical devices. The following are some major application scenarios for SMT Red Glue Technology:

1. Automotive Electronics

In the automotive industry, electronic components face harsh environmental conditions, including high temperatures, humidity, and vibrations. To ensure the reliability and stability of automotive electronics, SMT Red Glue Technology is widely used to secure and protect onboard electronic components. Red glue plays a vital role in automotive electronics by effectively reducing the risks of component loosening and detachment, thus enhancing the durability of automotive electronic systems.

2. Aerospace

In the aerospace sector, aircraft must withstand challenging aerodynamics and climatic conditions while maintaining high mechanical strength. SMT Red Glue Technology is applied to secure various electronic components within aircraft, including flight controllers, communication devices, and navigation systems. The use of red glue prevents components from loosening due to vibrations and impacts, ensuring stable operation of aircraft under high-speed and high-pressure conditions.

3. Medical Devices

In medical device manufacturing, SMT Red Glue Technology is employed to secure and protect various medical electronic components, such as pacemakers, medical monitoring instruments, and imaging devices. The application of red glue enhances the durability and stability of medical devices, reducing the risks of component detachment and damage, thereby improving their performance and reliability.

Advantages of SMT Red Glue Technology

As an auxiliary process, SMT Red Glue Technology offers several advantages to electronics manufacturing:

1. Enhanced Electronic Assembly Quality: SMT Red Glue Technology ensures precise positioning and fixation of electronic components on the PCB, preventing component loosening and detachment caused by vibrations, impacts, or temperature fluctuations.

2. Improved Reliability: The use of red glue provides additional mechanical support to electronic components, enhancing the durability and stability of electronic products and extending their lifespan.

3. Moisture and Corrosion Resistance: Certain SMT red glue materials exhibit resistance to moisture and corrosion, effectively safeguarding electronic components from moisture-related damages and corrosion in challenging environments.

4. Increased Production Efficiency: Automated red glue printing and curing processes improve production efficiency, reducing manual operations and thereby lowering manufacturing costs.

Conclusion

In summary, SMT Red Glue Technology is an indispensable part of SMT technology, providing critical protection and support to electronic assemblies. In automotive, aerospace, and medical industries, the application of SMT Red Glue Technology enhances the stability, reliability, and durability of electronic products. As electronic products continue to demand higher performance and reliability, SMT Red Glue Technology will play an increasingly crucial role in future developments.