SMT stencil cleaning method.

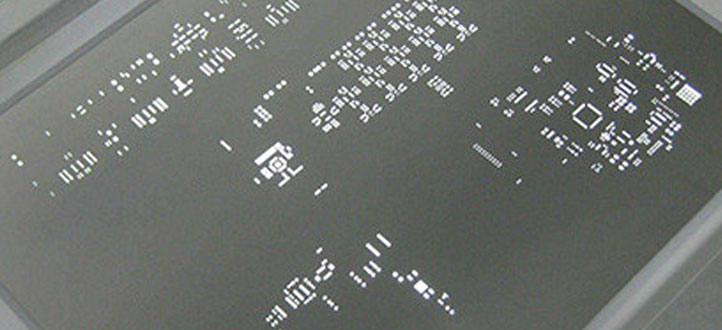

SMT steel mesh, an essential tool in the PCB assembly process, is used for solder paste printing or adhesive application. Its main function is to accurately apply solder paste to the PCB pads, facilitating the subsequent soldering process. However, over time, the steel mesh may encounter issues like clogged apertures or solder paste buildup, which can lead to printing quality problems. To mitigate these issues, operators often clean the steel mesh promptly based on factors such as usage conditions and duration. Let's delve into the cleaning process of SMT steel mesh.

There are two conventional methods for cleaning SMT steel mesh: manual cleaning and machine cleaning. Manual cleaning involves using cleaning agents, brushes, steel mesh paper, and an air gun. First, secure the steel mesh on a mesh frame and moisten the board surface with the cleaning agent. Gently brush the apertures using a soft brush, then pour an appropriate amount of cleaning agent (typically alcohol or board wash) on the steel mesh paper and wipe away the residual solder paste from the mesh surface and apertures. Next, use clean steel mesh paper to dry the surface, and finally, use an air gun to blow away any remaining moisture or impurities. After cleaning, thoroughly inspect the steel mesh to ensure there are no residual impurities or clogged apertures.

In cases where the steel mesh has accumulated solidified solder paste due to prolonged storage, manual cleaning may not effectively remove all residues. For such situations, a steel mesh cleaning machine is often used. There are two common types of machines: ultrasonic and pneumatic. Ultrasonic cleaning agents can be either immersion-based or spray-based. The working principle involves high-frequency oscillation to dislodge contaminants. When using an ultrasonic cleaning machine, first fill the reservoir with sufficient cleaning agent, then set the cleaning and drying durations, and wait for the machine to complete the process. Pneumatic cleaning machines, on the other hand, use compressed air as the power source for cleaning the steel mesh.

Currently, as steel mesh cleaning machines become more prevalent, the manual cleaning method has gradually been phased out due to increased production efficiency. Machine cleaning not only saves labor and time costs but also delivers better cleaning results. Proper cleaning of the steel mesh is crucial not only after use but also before and during use. Additionally, when storing the cleaned steel mesh, ensure the storage area is clean and tidy, and avoid stacking or placing other objects on the mesh to prevent deformation of the steel plates, mesh apertures, or frames, which may affect subsequent use.