What are the reasons that affect the quality of SMT steel mesh?

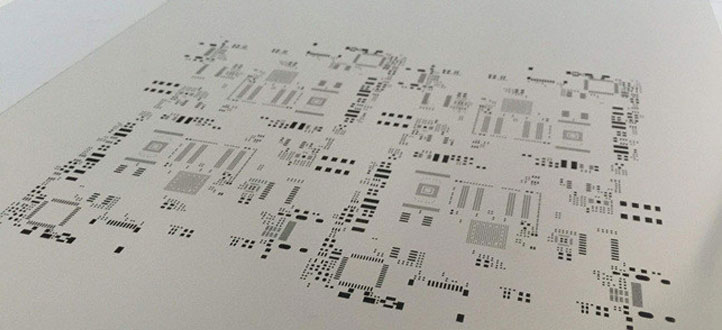

In the PCB assembly process, solder paste printing is a critical step, and the steel net is an essential tool required for solder paste printing. During the fabrication of the steel net, several factors can lead to quality issues, and the quality of the steel net directly affects the effectiveness of solder paste printing. So, what are the factors that influence the quality of the steel net? Let's find out!

1. Steel Net Aperture Design:

The aperture design of the steel net is the most significant factor affecting its quality. Insufficient aperture accuracy can result in defects such as bridging or insufficient solder during solder paste printing. Therefore, when designing the steel net aperture, it is essential to consider the selection of the fabrication process and the control of aperture accuracy.

2. Steel Net Fabrication Process:

Improper selection of the steel net fabrication process can also affect its quality. There are three common methods for fabricating steel nets: laser cutting, electroforming, and chemical etching. Each method has its advantages and disadvantages, so the choice of steel net fabrication process should be based on the specific requirements of the PCB.

3. Steel Net Materials:

The materials used for SMT steel nets also impact their quality. The overall structure of the steel net includes steel sheets, frames, and mesh. Stainless steel is commonly used for steel sheets, and different grades like 216, 301, and 304 are available. Generally, it is recommended to choose 304 stainless steel. For the mesh, stable tension polyester mesh is preferred, and the frame material must have excellent flatness and be able to withstand a certain level of process stress.

4. Steel Net Fabrication Data and Usage:

The completeness of the steel net fabrication data and the appropriate usage method also influence its quality. The completeness of fabrication data directly affects the quality of the steel net. Generally, the fabrication data should have clear data standards, and the more comprehensive, the better. Improper usage methods, such as placing the steel net unevenly during printing or excessive pressure from the solder paste printing machine, can lead to damage and affect the quality of the steel net.

5. Cleaning and Storage of Steel Nets: Timely cleaning and proper storage are also factors affecting the quality of steel nets. Steel nets are used for printing solder paste or adhesive, and if not cleaned promptly, cured solder paste or adhesive may clog the apertures and result in poor printing quality. Therefore, regular cleaning of the steel net is essential. After cleaning, the storage area should be clean and tidy, and steel nets should not be stacked or have any foreign objects placed on them to avoid deformation of steel sheets or frames, which could affect future usage.