What is included in the BOM table?

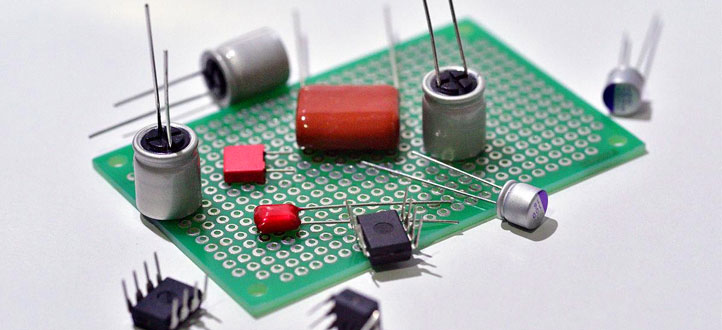

In the process of PCB assembly, the Bill of Materials (BOM) is an indispensable and crucial document. The BOM is a detailed list that outlines all the components, parts, and materials required for assembling the printed circuit board. Whether it's a small-scale consumer electronics product or a complex industrial device, the BOM plays a pivotal role in ensuring successful PCB assembly. Let's delve into the purpose and contents of the BOM.

The Role of BOM

The BOM serves several purposes during PCB assembly:

1. Clear Inventory: The BOM provides a clear list of all the components, parts, and materials needed. This helps ensure that no critical elements are overlooked.

2. Procurement Guide: The BOM offers information about manufacturers, model numbers, quantities, and more for each component, providing clear guidance to the procurement team to accurately source the required parts.

3. Cost Estimation: Including cost information for each component, the BOM aids in estimating the overall cost and contributes to budget planning.

4. Production Planning: The BOM guides the production team in scheduling the required parts and materials at the right time, ensuring a smooth production process.

5. Parts Management: The BOM records the status, lifecycle information, and alternate parts for each component, assisting in inventory and supply chain management.

Contents of BOM

A typical BOM includes the following information:

1. Component Name: Lists the name of each component, such as chips, resistors, capacitors, connectors, etc.

2. Component Description: Provides a detailed description of each component, including model numbers, package types, specifications, and more.

3. Manufacturer and Supplier: Lists the manufacturer and supplier for each component to facilitate procurement of the required parts.

4. Manufacturer Part Number (MPN): The unique identifier assigned by the component manufacturer for each part.

5. Supplier Part Number: The unique identifier assigned by the supplier for each part.

6. Quantity: Specifies the quantity of each component required to ensure an adequate supply for assembly.

7. Reference Designator: For components used multiple times on the PCB, this indicates their locations on the circuit diagram.

8. Value: Indicates the actual value for components like resistors, capacitors that require marking.

9. Notes: Additional instructions or notes, possibly including special requirements, alternate parts, etc.

10. Cost Information: Provides cost information for each component, aiding in overall cost estimation.

11. Part Status: The status of each part, such as in stock, pending purchase, or discontinued.

12. Package Type: The packaging type of the part, like tray, reel, tube, etc.

13. Lifecycle Status: The lifecycle status of the part, whether active, discontinued, transitioning, etc.

The significance of the BOM in PCB assembly is undeniable. It provides a foundation for coordination and collaboration among different teams, ensuring the smooth assembly and production of the circuit board. Whether it's a simple prototype or a sophisticated industrial-grade product, the BOM is one of the key factors for successful PCB assembly.