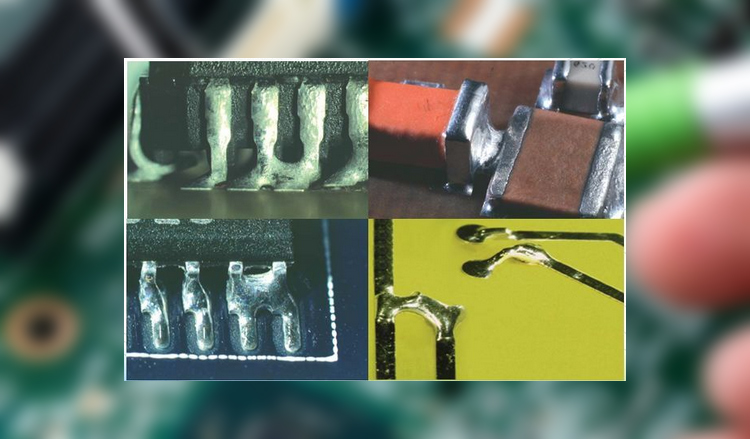

Reasons for SMT bridging

The bridging phenomenon not only affects the appearance of the product but also affects the electrical performance and reliability, causing short circuits between solder joints on the circuit board, thereby affecting the normal operation of the circuit board. Therefore, measures must be taken to reduce or eliminate the occurrence of SMT bridging.

Causes:

1. Excessive solder: If too much solder is used in the SMT process, the solder will flow between adjacent pads during soldering, resulting in bridging.

2. High solder viscosity: If the solder viscosity is too high, the solder cannot be evenly distributed on the pad during soldering, resulting in bridging.

3. High welding temperature: If the welding temperature is too high, the solder will melt excessively and flow between adjacent pads, resulting in bridging.

Solutions:

1. Control the amount of solder: Using an appropriate amount of solder can reduce the occurrence of bridging. In the SMT process, the appropriate amount of solder should be determined based on the size and shape of the pad.

2. Optimize the welding process: Properly adjusting welding temperature, time, and pressure can reduce the probability of bridging. In the SMT process, welding process parameters should be optimized based on factors such as pad material, size, and shape to ensure the stability of the welding process.

3. Use automated equipment: Automated equipment can precisely control the welding process, thereby reducing the occurrence of bridging. Automated equipment can ensure the stability and consistency of the welding process by precisely controlling welding temperature, time, and pressure.

4. Inspect and clean welding equipment: Regularly inspecting and cleaning welding equipment can ensure its normal operation and reduce the occurrence of bridging. In the SMT process, welding equipment should be inspected and cleaned regularly to ensure its normal operation and avoid bridging caused by equipment failure or poor cleaning.

In summary, to reduce or eliminate the occurrence of SMT bridging, comprehensive measures need to be taken, including controlling the amount of solder, optimizing the welding process, using automated equipment, and inspecting and cleaning welding equipment. Only through the comprehensive application of these measures can the occurrence of SMT bridging be effectively reduced, and the quality and reliability of the product be improved.