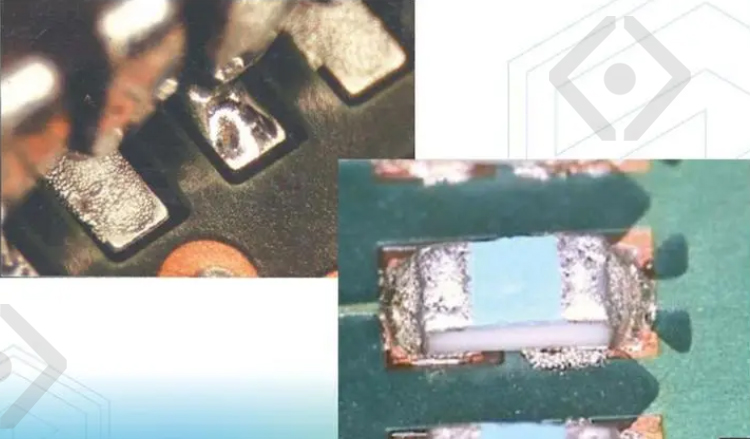

Reasons and solutions for SMT cold welding products

There are several reasons for the occurrence of SMT cold soldering:

Insufficient temperature: If the soldering temperature is insufficient during the SMT process, the solder cannot fully wet the pad or lead, resulting in poor bonding. This may be caused by inaccurate temperature control of the soldering equipment or short soldering time.

Insufficient solder volume: Insufficient solder volume may also cause cold soldering. If the solder volume is insufficient, the pad or lead cannot be fully wetted, resulting in poor soldering.

Contamination of the pad or lead surface: Contaminants such as oil and oxide on the pad or lead surface can also affect the soldering quality and cause cold soldering.

Excessive soldering speed: If the soldering speed is too fast, the solder does not have enough time to wet the pad or lead, resulting in cold soldering.

Inappropriate solder alloy composition: If the solder alloy composition is inappropriate, it can also affect the soldering quality and cause cold soldering.

To avoid the occurrence of cold soldering, it is necessary to strictly control soldering parameters, such as soldering temperature, soldering time, and solder volume, and ensure the cleanliness of the pad or lead surface during the production process.

To solve the problem of SMT cold soldering, the following solutions can be adopted:

Increase the soldering temperature: By increasing the soldering temperature, the solder can fully wet the pad or lead, thus forming a good solder joint.

Increase the solder volume: Increasing the solder volume can improve the quality of the solder joint and avoid cold soldering.

Clean the pad or lead surface: Ensuring the cleanliness of the pad or lead surface can avoid the influence of contaminants on the soldering quality and avoid cold soldering.

Adjust the soldering speed: Adjusting the soldering speed appropriately can ensure that the solder has enough time to wet the pad or lead, avoiding cold soldering.

Select the appropriate solder alloy: Choosing the appropriate solder alloy can improve the soldering quality and avoid cold soldering.

Strengthen quality control: Strengthening quality control and ensuring the accuracy and stability of soldering parameters can effectively avoid cold soldering.

In summary, by adopting the above measures, SMT cold soldering problems can be effectively solved, and the quality and production efficiency of soldering can be improved.