Why is solder ball produced during SMT welding?

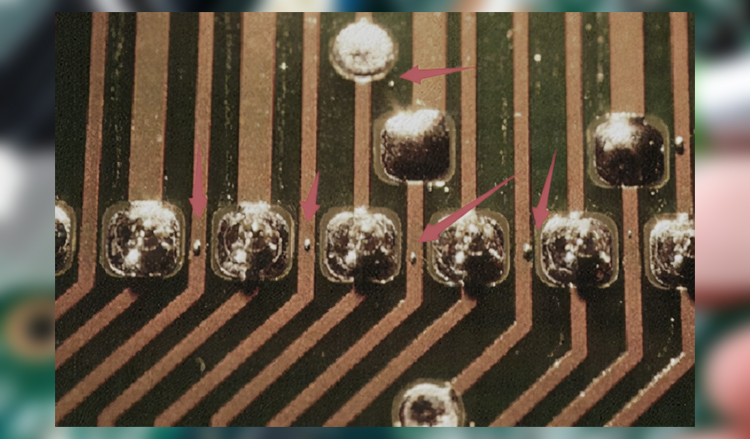

The so-called solder balls are small ball-shaped beads formed by the solder paste after welding, so they are also called solder spheres. The main reasons for the generation of solder balls are as follows:

1. Poor solder paste printing: When the solder paste printed on the component pads is excessive, the excess solder paste is easy to form solder balls when the solder paste melts during welding.

2. PCB or component dampness: If the PCB or electronic components are too humid or have too much moisture, the solder paste may burst during the welding process, causing solder balls to form.

3. Improper use of soldering iron: In the rework process, if the soldering iron is used to add solder too quickly, solder may splatter and form solder balls.

The above are the main reasons for the generation of solder balls. We can find corresponding solutions based on the above points. If it is a printing problem, we can control it from the stencil and the amount of solder paste used. If it is due to dampness of the board or components, we can dry them before welding. If it is a problem with the soldering iron, the operator needs to be careful.

Solder balls, bridging, tombstoning, and other phenomena are common defects in the PCBA welding process. The causes and hazards of each defect are different. Solder balls/dross are not fixed, and if not cleaned, they may fall off during the product's use. If solder balls run between the component pins, it may cause a circuit short circuit, resulting in product failure or even board burning. Therefore, in the PCBA welding process, we should be as careful as possible to avoid such defects.