What is the cause of the phenomenon of smt welding tombstoning?

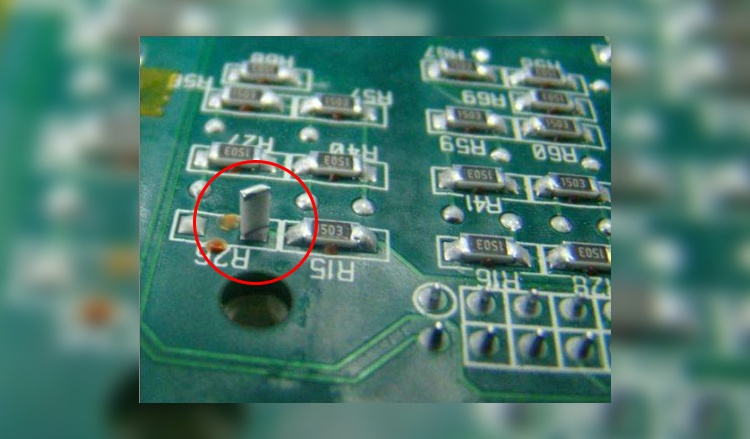

The tombstone effect refers to the soldering defect caused by the lifting of the component during the reflow soldering process due to unbalanced surface tension on both ends of the component. It is also called the bridging effect or Manhattan effect in the printed circuit board industry.

The reason for the tombstone effect is that the surface tension on both ends of the component is unbalanced during the reflow soldering process. If the tension is unbalanced, the end with lower tension will lift up when the solder paste melts, causing the entire component to lift and resulting in solder joint failure. Smaller components are more prone to the tombstone effect. Therefore, the cause of the tombstone effect is the unbalanced surface tension on both ends of the component, and the reasons for the unbalanced surface tension are mainly:

1. Uneven soldering temperature: During the reflow soldering process, there are three temperature zones - preheating, heating, and cooling. If the temperature is insufficient during preheating or the preheating time is too short, or if the temperature curve in the heating zone is not well controlled, the temperature in the furnace will be uneven, causing uneven heating of the PCB, resulting in unbalanced surface tension on both ends of the component, and ultimately leading to the tombstone effect.

2. Component issues: If the weight of the electronic component is insufficient or its volume is too small, it will increase the probability of the tombstone effect.

3. Solder paste issues: If the solder paste on the component is too thick during the printing process, it can also cause the tombstone effect.

4. Improper pad design: If the pad design is not symmetrical or the shape and size of the pads are inconsistent, it can cause the component to slide during the wetting process, resulting in the tombstone effect.

5. Placement offset: If there is an error in the placement coordinates during the SMT assembly process, it can also cause the tombstone effect.

Tombstone effect and bridging effect are common soldering defects in PCBA assembly. Each defect has different causes. For the tombstone effect, there are more reasons than those mentioned above, but most of them are caused by the reasons mentioned above. In addition to these reasons, other factors such as the thickness of the stencil or the pressure of the solder paste printing machine can also cause the tombstone effect. Based on these reasons, we can find reasonable solutions, such as selecting larger and heavier components whenever possible, and performing regular maintenance on the placement machine to reduce placement errors.