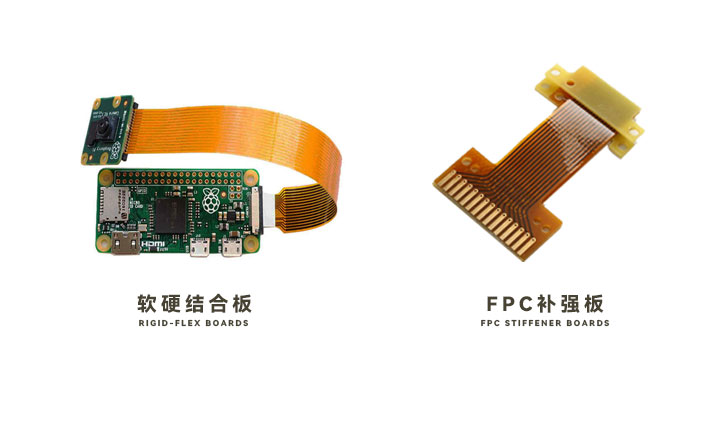

Differences Between FPC Stiffener Boards and Rigid-Flex Boards?

FPC stiffener boards and rigid-flex boards are common types in the PCB manufacturing field. Many people unfamiliar with PCBs may find it challenging to distinguish between them. Let’s explore the differences between these two types.

1,Structural Differences

Although both FPC stiffener boards and rigid-flex boards have both flexible and rigid parts, their main structures are different:

FPC Stiffener Boards: The main structure is flexible, with rigid materials added in specific areas to enhance mechanical strength.

Rigid-Flex Boards: The main structure includes both rigid and flexible parts, combining flexible circuits and rigid boards.

2,Design Differences

FPC Stiffener Boards: The design is relatively simple, primarily adding stiffener materials to specific areas of the flexible board. These stiffener materials usually do not have any traces and are only mechanically connected without electrical connections, resulting in lower complexity.

Rigid-Flex Boards: The design is more complex because rigid-flex boards have traces on the rigid materials. They require both mechanical and electrical connections. The design must consider the integration of rigid and flexible parts and their electrical and mechanical connections, leading to higher design and verification costs.

3,Cost Differences

FPC Stiffener Boards: Mainly use flexible substrates and stiffener materials, resulting in lower material costs.

Rigid-Flex Boards: Use both flexible and rigid substrates, along with specialized adhesives and copper cladding, leading to higher material costs.

4,Manufacturing Process Differences

FPC Stiffener Boards: The manufacturing process is relatively simple, requiring only the addition of stiffener layers to the flexible circuit board.

Rigid-Flex Boards: The manufacturing process is more complex, involving multiple laminations, drilling, and plating steps, making the process more demanding and intricate.

In summary, FPC stiffener boards and rigid-flex boards differ significantly in terms of structure, design, cost, and manufacturing processes. FPC stiffener boards are suitable for applications requiring lightweight and flexibility, while rigid-flex boards are ideal for scenarios needing high reliability and complex designs.