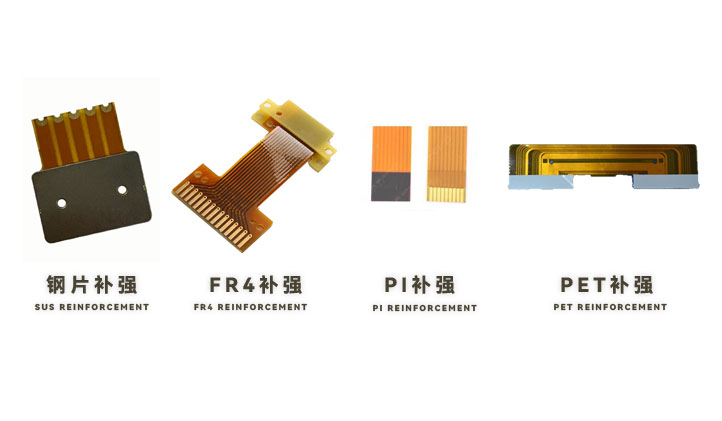

What are FPC reinforcing materials?

FPC boards are widely used in precision products due to their unique lightness and flexibility. However, in practical applications, FPCs face the challenge of insufficient mechanical strength. This issue can affect the stability and reliability of the products, thereby shortening their lifespan. Therefore, enhancing the mechanical strength of FPCs is crucial, and using reinforcement materials is the best solution to this problem. This process is often referred to as FPC reinforcement. Let’s take a closer look at the common reinforcement materials used for FPCs.

1. Polyimide (PI) Reinforcement

Polyimide (PI) is one of the most common reinforcement materials, known for its excellent high-temperature resistance and mechanical strength. PI reinforcement is typically applied to the gold finger areas of flexible boards. It maintains stable performance in high-temperature environments, making it suitable for applications that require frequent bending or high mechanical stress.

2. Glass Fiber Reinforced Epoxy (FR4) Reinforcement

FR-4 is a common PCB rigid board material, primarily used for making rigid boards but also usable as a reinforcement material. FR4 offers good mechanical properties and electrical insulation, and its relatively low cost makes it suitable for reinforcing flexible boards in cost-sensitive, low-end products.

3. Stainless Steel Reinforcement

Stainless steel reinforcement is made from stainless steel material, providing excellent mechanical strength and flatness. It is typically used to reinforce areas on flexible boards where chips are mounted, enhancing the strength of these regions. Due to the higher cost of stainless steel, it is usually employed in mid- to high-end products.

4. Polyester (PET) Reinforcement

Polyester (PET) reinforcement materials are not heat resistant and are relatively inexpensive. Therefore, they are generally used in low-end products that do not require high-temperature resistance. Although not commonly used in production, PET reinforcement still has its market in specific low-end applications.

These are the most common reinforcement materials for FPCs. FPC reinforcement typically focuses on specific areas of the flexible board to improve mechanical strength in those regions. The choice of reinforcement material depends on the specific requirements of the product. By carefully selecting and using these reinforcement materials, you can significantly enhance the reliability and lifespan of FPCs, allowing them to better withstand various complex and demanding environments.