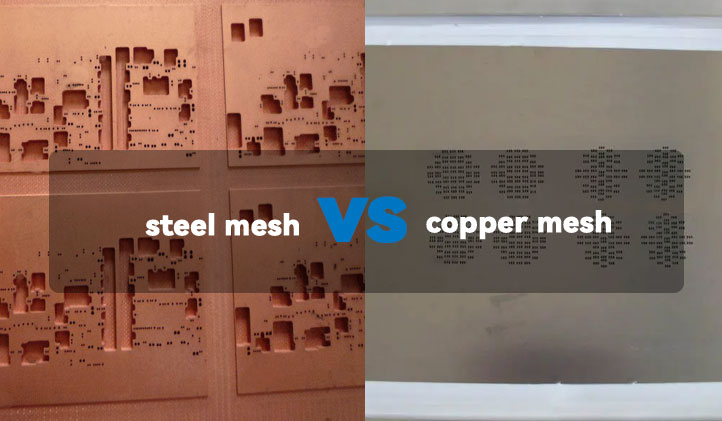

The difference between SMT steel mesh and copper mesh?

Differences Between SMT Steel and Copper Stencils:

1,Durability:

Copper Stencils: Copper has a lower hardness, making it more susceptible to wear, deformation, and corrosion. Consequently, copper stencils have a shorter lifespan and lower durability.

Steel Stencils: Made from stainless steel, these stencils exhibit excellent hardness and corrosion resistance, resulting in a longer lifespan and greater durability.

2,Precision:

Steel Stencils: These stencils offer high precision in aperture creation, making them suitable for high-demand, high-density, and high-precision solder paste printing.

Copper Stencils: Due to the material properties, copper stencils have lower precision in aperture creation and are typically used for lower-demand solder paste printing applications.

3,Cost:

Copper Stencils: Made from copper, these stencils are less expensive, making them a cost-effective choice for applications with limited budgets and lower precision requirements. Steel Stencils: Constructed from stainless steel, these stencils are more costly, but they are ideal for products requiring high quality and precision.