What is a PCB Gerber file?

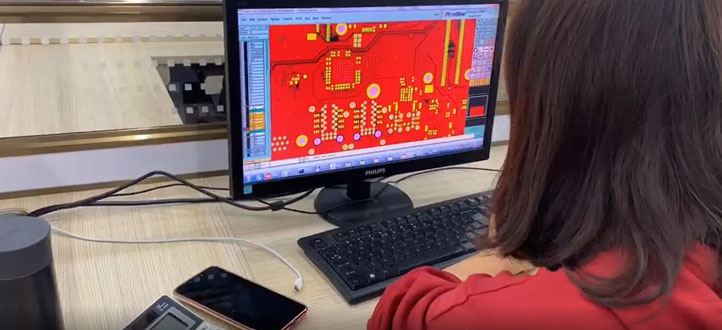

Gerber files are essential data files in the PCB assembly process, playing a crucial role. PCB Gerber files are a standardized file format for printed circuit board manufacturing, used to convert PCB design data into image files for PCB manufacturers. They contain layout information, wire paths, pads, hole positions, and other critical manufacturing details of the circuit board. This article will delve into the importance, composition, and application of PCB Gerber files in PCB manufacturing.

The Importance of PCB Gerber Files

In the process of PCB design and manufacturing, PCB Gerber files play an extremely important role. They act as a bridge for data exchange and collaboration between design engineers and manufacturing companies, ensuring that the PCB design can be accurately replicated in the manufacturing process. Being an open standard format, Gerber files can be read and understood by almost all PCB manufacturers, providing design engineers with a wide range of choices and flexibility.

Composition of PCB Gerber Files

PCB Gerber files consist of multiple text files, with each file representing different circuit board layers and manufacturing information. Common Gerber file layers include:

1. Component Placement Layer: Contains the layout, pin positions, and assembly information of all electronic components.

2. Copper Layer: Displays the wire paths and copper foil patterns on the circuit board.

3. Solder Mask Layer: Identifies the locations and dimensions of solder pads used for electronic component soldering.

4. Silkscreen Layer: Contains text, markings, and graphics information on the circuit board, used for component identification and product information.

5. Solder Resist Layer: Displays areas on the circuit board covered with solder resist to protect the circuit and prevent short circuits.

6. Drill File Layer: Identifies the hole positions and dimensions on the circuit board, used for hole drilling.

Application of PCB Gerber Files in PCB Manufacturing

PCB Gerber files play a crucial role in the PCB manufacturing process. Firstly, manufacturing companies use Gerber files to preview the circuit board design, ensuring its consistency with the design drawings and meeting the requirements. Secondly, manufacturing companies use Gerber files to create photomasks, transferring the circuit board patterns onto photosensitive-coated circuit board surfaces.

This process involves photolithography and pattern transfer techniques. By using Gerber files to control photolithography equipment, the patterns are precisely transferred onto the circuit board, forming the required circuit patterns. Subsequently, the circuit board undergoes processes such as etching and metal plating to eventually become a complete PCB.

Conclusion

In conclusion, PCB Gerber files are a standardized file format for converting PCB designs into manufacturing images, playing a crucial role in modern electronic manufacturing. They serve as a bridge between design engineers and manufacturing companies, ensuring that PCB designs can be accurately replicated in the manufacturing process. Through PCB Gerber files, PCB manufacturing achieves efficient, precise, and collaborative processes, providing us with various advanced electronic devices and products. Whether it's consumer electronics or high-end equipment in the industrial and communication sectors, PCB Gerber files play an indispensable role in all of them.