What are the types of PCB?

PCB assembly is an indispensable part of modern electronics manufacturing, and different types of PCBs play different roles in the PCB assembly process. PCBs (Printed Circuit Boards) can be classified into various types based on their structures, applications, and performance requirements. Below, we will introduce some common types of PCBs and their characteristics.

Single-Sided PCB:

Single-Sided PCB is one of the simplest and most common types. It has circuit copper traces on only one side, while the other side is usually either without copper connections or covered with solder mask. Single-Sided PCBs are suitable for simple electronic circuits where components can only be mounted on one side of the board. These PCBs are commonly used in low-cost and low-complexity electronic products such as electronic toys and household appliances.

Double-Sided PCB:

Double-Sided PCB has circuit copper traces on both sides, allowing components to be mounted on both sides. Connections between the two sides are achieved using vias, which facilitate signal transmission and circuit interconnections. Double-Sided PCBs are more complex than single-sided ones, making them suitable for medium-complexity electronic devices like computer hardware and industrial controllers.

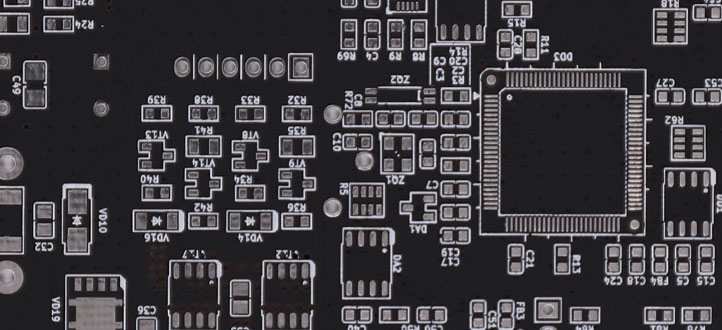

Multi-Layer PCB:

Multi-Layer PCBs are created by stacking multiple layers of circuit boards, interconnected by internal circuitry and vias. They are suitable for complex electronic circuits and provide higher wiring density and better signal integrity. Multi-Layer PCBs are widely used in high-performance computers, communication equipment, and consumer electronics. Rigid PCB:

Rigid PCBs are made from rigid substrate materials and are suitable for most conventional electronic devices. They are the most common type of PCB, fulfilling the requirements of the majority of standard electronic products.

Flex PCB:

Flex PCBs are manufactured using flexible substrate materials, allowing them to be bent and folded. They are used in electronic devices that require flexible layouts, such as mobile phones and wearable devices.

Rigid-Flex PCB:

Rigid-Flex PCB combines the characteristics of rigid and flexible boards, enabling flexible connections and stable support. This type of PCB is suitable for special-shaped electronic devices, including foldable phones and curved electronic devices.

High-Frequency PCB:

High-Frequency PCBs are used for high-frequency signal transmission, with low signal loss and good impedance control. They are commonly used in radar, communication equipment, and radio frequency electronic products.

High-Speed PCB:

High-Speed PCBs are designed for high-speed signal transmission, with low signal delay and electromagnetic interference suppression. They are extensively used in high-performance computers and high-speed communication equipment.

Metal Core PCB: Metal Core PCBs use metal (usually aluminum/copper) as a thermal conductive material, making them suitable for high-power electronic devices requiring excellent heat dissipation. They are commonly used in LED lighting products and high-power electronic modules.

HDI PCB:

High-Density Interconnect (HDI) PCBs feature high-density routing and fine line and spacing, making them ideal for compact high-performance devices such as smartphones and tablets.

In addition to the common PCB types mentioned above, there are also some special types, such as Buried Via PCBs and Blind Via PCBs. These are designed for more complex circuit requirements, allowing for higher wiring density and better signal transmission performance.

Overall, the different types of PCBs cater to various application scenarios and performance requirements. Selecting the appropriate PCB type is crucial in ensuring product quality, performance, and reliability in electronics manufacturing.