Introduction to Immersion Gold and Electroplated Gold Processes

In PCB manufacturing, surface treatment processes directly affect the reliability and manufacturability of the circuit board. Among them, electroplated gold and immersion gold are two commonly used gold-plating techniques, each with distinct characteristics in terms of principles, coating thickness, cost, and application scope.

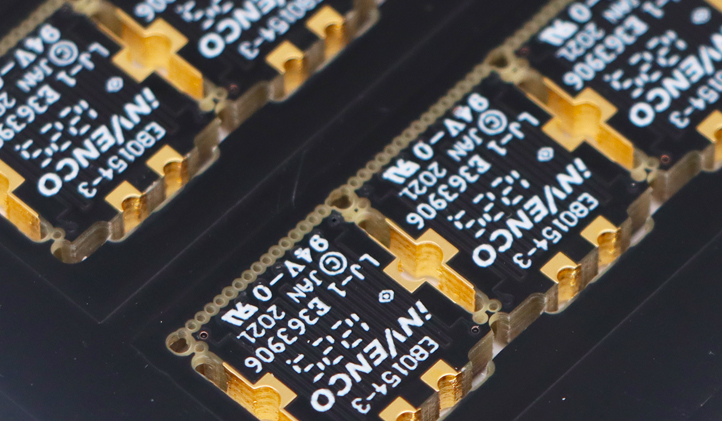

Electroplated gold is an electrochemical deposition process in which gold ions are reduced and deposited onto copper or nickel surfaces by applying current in an electrolyte solution. The coating thickness is controllable, typically ranging from 1 to 5 μm, and can be adjusted as needed. Factors such as current density, temperature, bath composition, and agitation conditions influence the uniformity and adhesion of the coating. The thick gold layer provides excellent wear resistance and conductivity, making it ideal for gold fingers, connector contacts, high-end switches, and relay terminals that require frequent mating or long-term stable connections. However, electroplated gold consumes more material and is relatively expensive. In addition, its thicker coating may affect the solderability of fine-pitch pads, making it less suitable for areas such as BGA or QFP packages.

Immersion gold, on the other hand, is a chemical displacement plating process. It does not require external current; instead, gold is deposited onto the nickel-coated copper surface through a chemical reaction. The standard ENIG (Electroless Nickel Immersion Gold) process typically involves electroless nickel plating, cleaning, and immersion gold steps. The gold layer is very thin—usually 0.05 to 0.1 μm—yet provides excellent surface flatness and uniformity. This prevents oxidation and ensures good solderability, which is why immersion gold is widely used for BGA pads, CSP/QFP packages, SMT component soldering areas, and other high-density PCBs that require superior surface planarity. Compared with electroplated gold, immersion gold uses less material and is more cost-effective, but its wear resistance is limited, making it unsuitable for high-frequency mating applications.

From a process perspective, electroplated gold relies on current-driven deposition to form a thick, durable layer, suitable for applications requiring mechanical strength and stable conductivity. Immersion gold, by contrast, relies on chemical reactions to create a thin, flat coating, making it better suited for high-density circuits where solderability and surface precision are critical.