What is the difference between PCB and SMT?

PCB (Printed Circuit Board) and SMT (Surface Mount Technology) are two integral concepts in electronic manufacturing. In the production of modern electronic devices, PCB assembly is a crucial step that involves the utilization of SMT techniques to mount electronic components onto the PCB. This article will explore the differences between PCB and SMT, as well as their significance in electronic manufacturing.

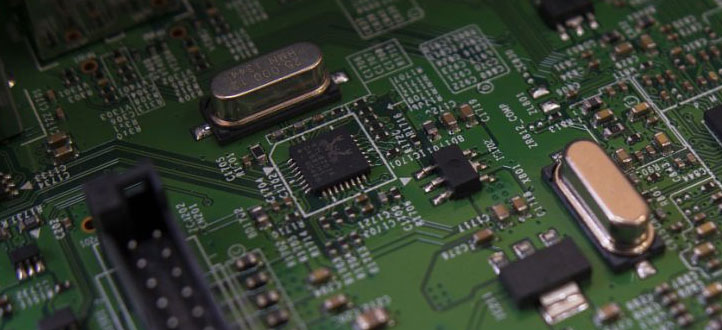

PCB serves as the foundation for electronic devices, achieved by laying conductive pathways and connecting electronic components on an insulating board. It acts as the skeletal structure, providing support and interconnection for various electronic elements. The primary function of PCB is to facilitate signal transmission and power supply through the use of conductive traces, electronic components, electrical connections, and assembly structures, thereby forming a complete electronic system.

On the other hand, SMT technology is a modernized method for soldering electronic components, primarily used for their mounting onto PCBs. Through SMT, electronic components can be directly placed on the surface of the PCB, eliminating the need for traditional pin or wire connections. This surface mount approach not only saves space but also enhances the reliability and production efficiency of electronic devices. SMT techniques involve precise placement of electronic components on the PCB's surface, followed by soldering them in place using molten solder. This soldering technique offers smaller form factors, higher reliability, and improved electrical performance, making it widely adopted in contemporary electronic manufacturing.

In summary, PCB and SMT are distinct yet interrelated concepts. PCB forms the backbone of electronic devices, while SMT technology provides an efficient means for mounting and connecting electronic components on PCBs. By combining PCB and SMT, it becomes possible to achieve high integration, compact designs, and reliable soldering connections, thereby propelling the advancement of modern electronic manufacturing.