The difference between SMT lead-free process and lead process?

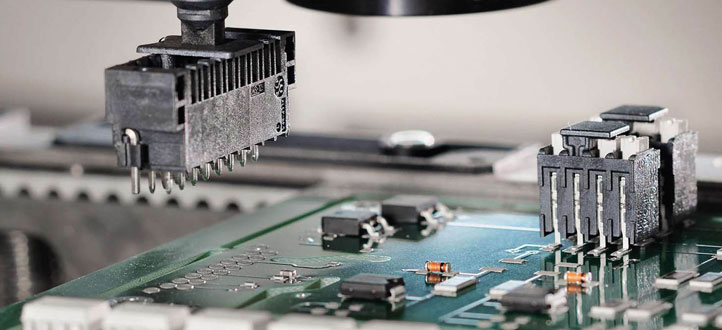

During the PCB assembly process, there are two common soldering methods known as leaded SMT (Surface Mount Technology) and lead-free SMT. These methods are used to solder Surface Mount Devices onto the PCB. They involve the use of different soldering materials and process parameters, with the key distinction being the solder paste used: leaded solder paste versus lead-free solder paste.

Leaded SMT is a traditional soldering method that utilizes leaded solder paste. The primary components of leaded solder paste are tin and lead (Sn-Pb), with a higher concentration of lead. Leaded solder paste has a low melting point, allowing it to liquefy at relatively low temperatures, making it convenient for soldering operations. In leaded SMT, the soldering temperature typically ranges from 180°C to 230°C. Leaded solder paste forms reliable solder joints when melted, providing good electrical connectivity. However, the presence of hazardous lead elements in leaded solder paste poses potential risks to the environment and worker health.

To reduce environmental and health risks, lead-free SMT has been increasingly adopted. Lead-free SMT employs lead-free solder paste, primarily composed of tin, silver, and copper (Sn-Ag-Cu). Lead-free solder paste does not contain hazardous lead elements, making it more environmentally friendly and safer. However, compared to leaded solder paste, lead-free solder paste has a higher melting point, typically requiring soldering at higher temperatures. The soldering temperature in lead-free SMT typically ranges from 220°C to 260°C, depending on the specific lead-free solder paste used. To accommodate lead-free SMT, manufacturers need to adjust soldering equipment, process parameters, and soldering time to ensure soldering quality and product reliability.

Lead-free SMT offers several advantages over leaded SMT. Firstly, lead-free SMT is more environmentally friendly, as it does not release harmful lead vapor, thereby reducing environmental pollution. Secondly, lead-free solder paste provides solder joints with higher reliability and durability, contributing to improved product quality and performance.

In conclusion, leaded SMT and lead-free SMT are two common soldering methods. Leaded SMT uses leaded solder paste, enabling soldering at lower temperatures but containing hazardous lead elements. Lead-free SMT utilizes lead-free solder paste, offering greater environmental friendliness and safety but requiring higher soldering temperatures and process adjustments. With increasing environmental awareness, lead-free SMT has gradually replaced leaded SMT as the mainstream choice and has gained wide application in the electronic manufacturing industry.