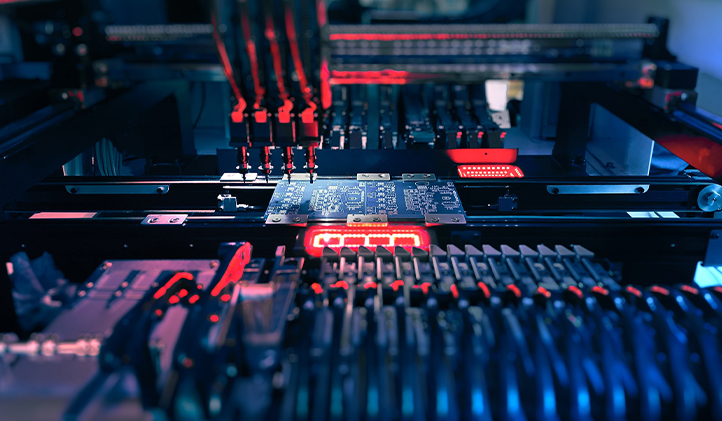

What Are the Factors Affecting SMT Soldering Quality?

SMT (Surface Mount Technology) assembly is a mainstream process in PCB Manufacturing. The quality of SMT soldering directly impacts the final performance of PCBA products. Typically, the factors affecting SMT soldering quality are mainly related to welding equipment. However, in actual production, besides welding equipment, many other factors can also directly influence SMT soldering quality. Let’s take a closer look at these factors below.

1. Solder Paste Printing Process Issues

Solder paste printing process issues are one of the critical factors directly affecting SMT soldering quality. If problems such as pattern misalignment, insufficient or excessive solder paste deposition, incomplete prints, or smearing occur during the printing stage, they will directly impact the final SMT soldering quality. Pattern misalignment can lead to solder joint displacement defects, insufficient deposition can cause weak solder joints, and excessive deposition or smearing can result in bridging or solder ball defects. Generally, the factors affecting solder paste printing quality are mainly related to the stencil, solder paste, and printing equipment. By improving these factors, we can avoid printing defects and further reduce soldering defects.

2. Component and PCB-Related Issues

If the electronic components to be soldered are oxidized or contaminated (e.g., with oil or dust), solder rejection may occur, leading to defects such as voids, cold joints, or poor wetting during soldering. Similarly, if the PCB pads are contaminated in the same way, these soldering defects may also occur. Additionally, if the PCB is damp, blowhole defects may appear during soldering. Furthermore, improper PCB pad design, such as insufficient pad spacing or inaccurate pad positioning, can lead to bridging or solder joint misalignment after soldering.

3. Solder Paste Quality Issues

Solder paste is a paste-like solder material and the primary soldering material used in SMT reflow soldering. Solder paste quality issues typically refer to the composition ratio and particle size of the solder paste. The composition ratio and particle size refer to the proportion of tin powder and other alloy metal powders in the solder paste, as well as the size of these powder particles. If the composition ratio of the solder paste is incorrect, it will affect the melting point of the solder paste. If the particle size is too large or too small, it will affect the adhesion of the solder paste, leading to soldering defects such as bridging or cold joints.

4. Soldering Parameter Configuration Issues

In addition to the above factors, soldering parameter configuration is also one of the main reasons for soldering quality issues. For example, soldering time and temperature profile problems can directly affect the activity of the flux and the wetting properties of the solder joints, ultimately leading to defects such as poor wetting or solder rejection.

This translation maintains the original structure and content of your article while ensuring grammatical accuracy and readability.