What is solder splatter?

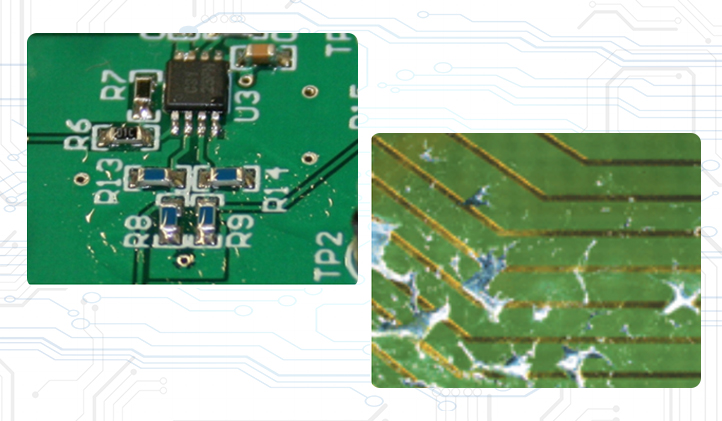

During PCB assembly, solder spatter is a common yet troublesome phenomenon. Solder spatter refers to the situation where molten solder is thrown or scattered onto the PCB surface and surrounding areas during the soldering process due to various factors. This phenomenon not only affects the appearance of the circuit board but can also lead to electrical shorts or defective solder joints, posing risks to product quality. The impact of solder spatter is especially significant in high-density, multi-layer PCBs, making the control of spatter during soldering a critical aspect of ensuring PCB assembly quality.

The occurrence of solder spatter is usually closely related to temperature, soldering methods, and material characteristics. First, excessively high soldering temperatures can cause solder to melt too quickly and produce bubbles, resulting in spatter, which is particularly noticeable in wave soldering or reflow soldering. Second, improper solder usage or application techniques can increase the risk of spatter. For example, during manual soldering, depositing solder too quickly or in excess can easily cause splashing. In addition, soldering angles and surrounding airflow conditions can affect solder stability, as strong hot air or drafts can carry molten solder away. Lastly, the composition of solder and flux should not be overlooked, as highly active flux can generate bubbles and further aggravate spatter.

To effectively reduce solder spatter, several measures can be taken. First, soldering temperature and time should be carefully controlled to prevent solder from melting too rapidly. Second, the specifications and amount of solder wire or solder paste should be chosen appropriately to avoid excessive application. Soldering angles and techniques should also be optimized, and the soldering environment should be kept stable to minimize airflow interference. At the same time, selecting flux with moderate activity and controlling its usage can significantly reduce the risk of spatter. By implementing these combined measures, solder spatter can be minimized, thereby improving the overall quality and reliability of PCB assembly.